The technique

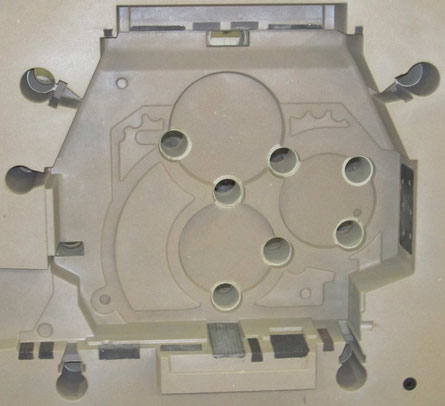

Construction and description of the Reibregenerator

The main components are:

- The grinding chamber

- The drive shaft with agitation kits

- The air cell with fluidization bed

- The fan

- The power control system

- The exhaust ventilation (on site)

Cleaning process

The crushed and foreign material free sand ist filled via a buffer into the grinding chamber.

The drive shaft, fitted with agitation kits, accelerates the sand and starts the grinding process.

There are three types of friction:

- Sand / Sand

-

Sand / Casing

-

Sand / Friction tool

The duration of the sand treatment depends on the sand impurity level and can be set to the respective requirements and operational conditions. The cleaning intensity is variable and cleaning

takes place gently without destroying the sand.

The abraded binder residues are sucked out during the cleaning process.

H33, new sand

After Pre attrition in feed tank

After final treatment in the Reibregenerator

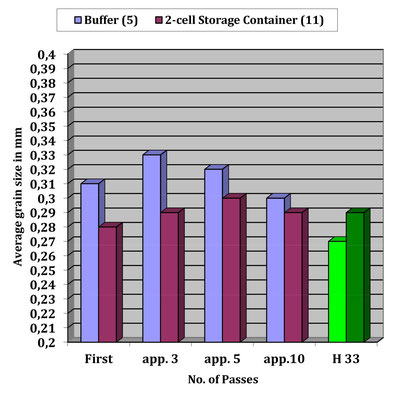

Grain size distribution of the reclaimed sand

Granulometric analyses versus reclaiming cycles (dry screening)

For the used sand H33, the actual value of the average grain size from the suppliers product data is shown (0,27 mm), and the value measured at the mixer outlet (0,29 mm) during moulding.

Overall, only negligible fluctuations in the average grain size in the reclaimed sand were noted in the peroid from the end of 2010 until today. The average grain size always was about 0,29 mm.

In the feed vessel, prior to final reclamation, the average grain size was about 0,01 to 0,04 mm higher than after the final grinding process.

The total loss during reclamation is since 2010 always at about 7,0 %.

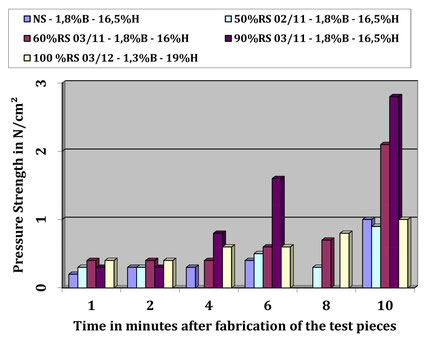

Compressive strength

Compressive strength of various sand mixtures and different reclamation levels

Adjacent figure of the compressive strength shows the bench life of the sand mixture.

From past experience we know that there should be a maximum pressure strength of about 1,0 N/cm² without sustainable harming the binder bridges by manipulations or moulding material

movements.

Important for the evaluation of the reclaimed sand for moulding are electrical conductivity (recommended < 800 µS, see literature) and the soda content (max. 0,15 %, see literature).

Both, the samples of the electrical conductivity of less than 500 µS and the sodium content to 0,15 %, showing values among the recommended data.

With the sand cleaned by Reibregenerator moulds as well as cores can be manufactured with up to 100 % amount of reclaimed sand.

Mould, which was made with 100 % reclaimed sand and was completed in the upper region with 100 % new sand.

Detail of a foundry mould of a large AL-casting, manufactured with 80 % reclaimed sand.

Technical data Reibregenerator

(Pat. EP2666562 / PCT/EP/2013/003548)

Type:

Operating mode:

Performance:

Batch size:

Batch time:

Power:

Size:

Transport size:

Transport weight:

Other types:

MRR 1-40, mobile version

batchwise

200-300 kg/h

40-50 kg/batch

5-14 minutes

18 kW

1.600 * 1.600 * 2.950 mm high

1.600 * 1.600 * 2.450 mm high

950 kg

RR 2-85 with an output of approx. 1.200 kg/h

RR 2-120 with an output of approx. 2.000 kg/h

Further models on request.